发布时间:2023-08-29

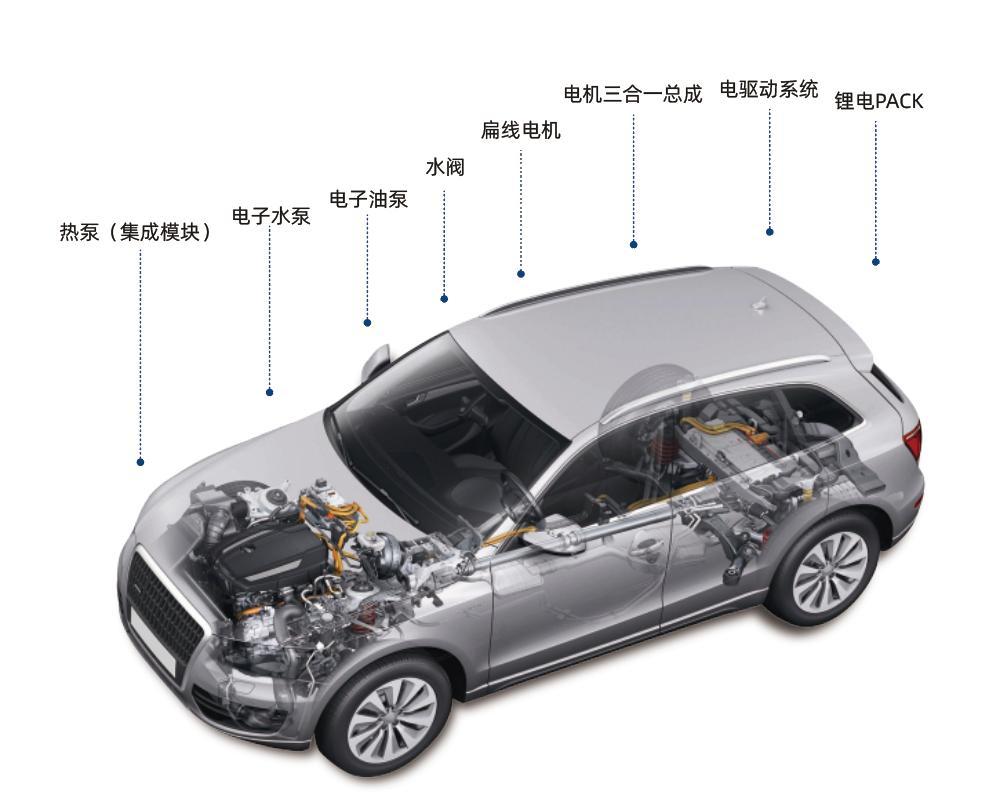

8月9日,比亚迪第500万辆新能源汽车正式下线,成为全球达成这一里程碑的车企。这标志着新能源汽车浪潮已席卷而来,随着汽车向电动化和智能化方向发展,对汽车能量管理的要求也越来越高。而直冷直热的热泵空调热管理系统是新能源汽车领域的新蓝海,随着热管理系统的崛起,作为该系统关键功能部件的热管理集成模块将相关零部件集成起来,通过车载计算机精确的控制各元器件的运转情况,保障各系统安全有序、高效的运转,极大得提升了整车性能和可靠性,同时,还节省了空间和成本,使得前舱整体更加标准化、美观化。

本土热管理企业已展现强大发展潜能

按照目前全球新能源汽车市场格局测算,2025年全球汽车热管理市场空间有望达到1200亿元,国内新能源乘用车热管理行业市场空间有望达757亿元。伴随着国内更多汽车品牌的诞生,给国内热管理零部件供应商提供更多尝试的机会,将有利于国内热管理系统企业的快速成长,从而打破原有供应链体系,进入新的汽车零部件成长期。其主要优势表现在以下几个方面。第一:本土配套响应更快,随着国内汽车开发周期的缩短,快速响应在整车开发周期中至关重要,而国内本土企业可以充分利用这一优势;第二,成本优势,相比于国际市场,国内具有更低的人工成本以及国产设备成本;第三,众多新势力品牌在企业发展初期,更加容易形成产业链粘性,共同成长。

▲图片来自于中科摩通实际案例

作为本土造车企业,哪吒汽车秉承“打破常规,创新科技让出行更自在”的企业使命,以“为人民造车”为理念,聚焦产品和前瞻技术,推动电动汽车的不断进化,未来科技发展趋势。在新能源汽车热管理系统集成化走出了自己的技术优势,主要可以有效地实现平台化,有利于规模化的批量生产以及成本的降低,并可以提升热管理效率,且在整车空间方面,可以节省更多的空间,给乘客提供更多的使用功能,哪吒汽车在推动电动汽车不断进化上交出了自己的答案。

中科摩通助力户用储能产品全球策略布局

中科摩通助力汽车企业做大做强

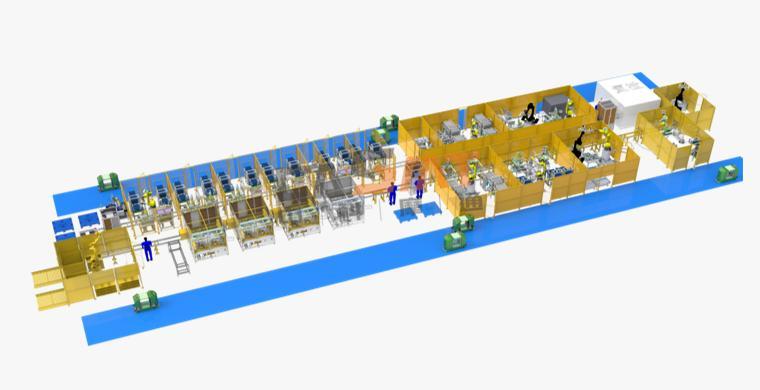

中科摩通此次与哪吒汽车展开战略合作,提供了具备前沿技术和预估了产业未来发展方向的全自动化智能产线,助力民族汽车品牌在新能源汽车领域腾飞。

▲图片来自于中科摩通实际方案

热管理模块总成自动化产线

- 兼容3种产品

- 产线整体节拍小于65s

- OEE大于85%

产线通过工序的4大核心模块解决了客户对于产品效率、成品率的高要求。

模块一:O型圈上料和破损检测

O型圈通过振动盘自动上料,小转盘上O型圈正反面破损检测。

模块二:O型圈涂油和装配

O型圈通过雾状喷油增加泣滑,O型圈通过专用夹爪装O型圈至部件。

模块三:机器人及视觉引导

机器抓取部件,视觉引导部件装入流道板。

模块四:压装与拧紧

伺服压机压紧部件,力与位移监控;拧紧枪视觉引导拧紧。

总成经过电测、外漏测试、内漏测试、流量测试的四步测试,保证产线装配产品的合格出货。

新能源汽车制造将成为智能制造领域的重要基石,带动高端装备制造、信息技术、人工智能等相关领域的快速发展。预计未来,新能源汽车制造将成为推动国民经济转型升级和推进智能制造的重要产业。我们期待与新能源产业一起在数字化、智能化方向上的不断突破和创新!

2025-03-24

中科摩通近期宣布,依托其在智能制造领域的技术积淀,已成功完成轮毂电机自动化生产线的研发及产业化布局。此举标志着中科摩通在新能源汽车核心零部件制造领域的战略版图进一步扩展,为行业技术革新注入新动能。中科摩通自成立以来,始终聚焦新能源汽车产业链的智能化升级需求,通过自动化、信息化与智能化技术的深度融合,为行业提供从研发到量产的全链条解决方案。公司此前已在热管理、扁线电机、线控底盘、电驱动、智能驾驶、储能电池等细分领域建立领先优势,并凭借快速交付能力与标准化产线设计赢得市场认可。中科摩通-智能生产车间此次布局轮毂电机自动化产线,是中科摩通响应行业技术变革的重要举措。轮毂电机作为新能源汽车驱动系统的前沿性技术,具有高度集成化、轻量化及能效优化的特点,但其规模化生产长期受制于工艺复杂性与装配精度要求。中科摩通凭借在运动控制、视觉检测、数据追溯等领域的核心技术沉淀,致力于攻克轮毂电机生产中的工艺瓶颈,推动该技术从实验室走向规模化应用。产线包含以下核心设备工艺:转子钢圈热套/转子插磁/定子壳体密封检测/电子模块装配/定转子总成/定子与轴装配/刹车盘装配等。在轮毂电机产线研发中,中科摩通延续了其“以技术创新引导市场”的理念。通过整合柔性化装配工艺、第三代性能测试等技术,公司构建了覆盖全生产流程的数字化解决方案,实现从零部件加工到成品组装的全程自动化与可追溯性。此外,中科摩通将模块化设计理念引入产线开发,未来可快速适配不同规格的轮毂电机产品,助力客户应对市场多样化需求。中科摩通-轮毂电机产品示意图轮毂电机技术的普及将重构传统汽车驱动系统,对底盘设计、能源管理及整车轻量化产生深远影响。中科摩通通过智能化产线的布局,不仅降低了客户的生产成本与工艺门槛,更以“智能生产+智慧服务”的模式,助力车企加速技术迭代。中科摩通目前已成功研发轮毂电机装配设备,将其纳入中科摩通新能源汽车智能装备的核心业务板块,与热管理、线控底盘等现有业务形成协同效应,打造覆盖新能源核心零部件的智能制造生态。中科摩通对轮毂电机自动化产线的加码,不仅是其技术实力的又一次展现,更是对新能源汽车产业变革趋势的精准把握。在“双碳”目标驱动下,随着智能化装备与核心零部件的深度融合,中科摩通有望引领新一轮产业升级浪潮,为中国智造在全球竞争中占据制高点提供关键支撑。2023-09-19

万亿储能大赛道中,户储是重要的一个场景,在2022年开启了“元年”时代,2023年大圆柱在储能领域已逐渐起量,并将持续保持高增长态势。40系列大圆柱电池因自身超强动力、超长续航、宽温程使用等优异性能,使其不断加速渗透家用储能领域。家用储能的市场需求仍处于高景气的状态,主要市场依旧分布在海外,据中国化学与物理电源行业协会储能应用分会测算,预计到2025年家用储能渗透率有望达28%,欧洲家用储能渗透率有望从2022年18%会提升至2025年56%。家用储能已经成为储能产业链的重要一环,也是未来的黄金赛道之一。 大圆柱电池产业链规模化发展从表面看,尽管大圆柱电池制造工序比传统小圆柱电池及其他形态电池更加简洁、高效,但对设备供应商、化工材料供应商和电动车企都提出了更高的技术要求。大圆柱电池工艺简单和高度标准化,以及整包层面结构减少、成组简单等特点,在整体成本上有一定优势,如果要想把优势变现,需要产业链各环节共同发力,才能达到规模化拐点。 ▲图片来自于中科摩通现场拍摄和实际方案 大圆柱电池产线量产之路基于大圆柱电池在性能方面的优势,众多厂家蓄势待发筹备量产产线,然而新兴技术的量产之路总是会有波折。大圆柱电池的产线既要满足量的提升,又要克服生产中精度、合格率等关键参数的困难。中科摩通助力万帮数字能源进一步布局大圆柱锂电市场,进行了整厂规划,家储和商储全套自动化解决方案,从智能仓储,AGV上料,模组装配焊接、PACK装配、AGV下料、成品测试、出库等全供应链整厂规划; ▲图片来自于中科摩通现场拍摄和实际方案 40系列大圆柱电芯储能模组PACK线 ▲图片来自于中科摩通实际方案 ▲图片来自于中科摩通现场拍摄和实际方案 ▲图片来自于中科摩通现场拍摄和实际方案 1)产线设计节拍30PPM+2)整线自动化率高达80%以上,包含自动上线、自动测试、自动入支架、自动激光焊接、整包自动下线等核心工艺3)关键工艺焊接参数定制化设计,焊接拉力>1000N,熔深熔宽满足强度和外观等要求;焊接压头环吹保护气的结构设计,有效降低飞溅,整机焊接良率控制在99.9%以上;焊接过程LDD 实时监控焊接状态,实时监控焊接熔深熔宽,极大的提高虚焊检出率。该产线生产的家储产品主要用于出口,产品品质要求高,市场发展有巨大潜力。 中科摩通成立于2019年,是一家专注于研发新能源产业智能装备整体解决方案的国家级专精特新小巨人企业,公司依托中科院江苏智能院、中科院天目湖储能院强大的科研技术力量,旨在为新能源产业提供自动化、信息化、智能化的生产解决方案。公司主营产品包含锂电池模组自动化产线,锂电池PACK自动化产线,锂电池储能系统自动化产线。公司已成功进入宁德时代、蜂巢能源、鹏辉锂电、科士达、万帮数字能源、新泉股份、康佳集团,通盛新能源等新能源汽车领域及储能系统集成头部客户。2023-08-29

在当前全球能源短缺、海外电价气价高涨的情况下,户用储能仍旧是率先突围的一环。在碳中和发展趋势下,业内对户用储能市场更是充满了信心,认为其将成为新能源行业继风电、光伏、电动车之外的第四条高速增长的赛道。“双碳”目标下,以光伏为代表的新能源在政策利好下迎来了快速增长。而随着储能技术成熟、成本下降,家庭场景也逐渐成长为新能源应用的重要领域。尤其是在海外市场,居民电价持续上涨之下,户用储能的经济性逐渐凸显,加之各国政府财政补贴,进一步推动其快速普及。 2022年,在全球经济复苏乏力、国际环境动荡不安的大背景下,储能行业迎来蓬勃发展的机遇,户用储能产业发展势头尤为强劲。欧洲是全球最大的户储应用市场,根据欧洲光伏产业协会去年12月发布的欧洲户用储能市场展望报告预测,2022年欧洲户用储能装机量预计达到3.9GWh,同比增长71%;在中性情况下,2023年装机量将达到4.5GWh,同比增速达到了16%。而长期来看,储能是支撑清洁能源装机增长的必要前提条件,因此其潜力较大,2023-2025 年全球储能装机预计持续向好,新增装机 CAGR 有望达到 57%,全球新型户用储能市场仍保持高速增长态势。 国内企业加速扩产户用储能产品全球能源转型持续推进,储能在未来电力系统中已是不可或缺的角色,且目前储能渗透率仍偏低,有巨大的成长空间。 ▲图片来自于中科摩通现场拍摄和实际方案 在全球储能需求高速增长的格局下,全球储能电芯中国厂商出货领先。储能电池已经是万亿级的超级赛道,在这个赛道上全速发展既要有对新能源的长远规划,也要深度挖掘属于自己的赛道。万帮数字能源是全 国 第一个在家庭场景里实现了光储充放、绿电交易整个系统应用的,实际运转下来,整个系统体验非常好,通过实干在家储方向开拓了新的细分赛道。 中科摩通助力户用储能产品全球策略布局此次中科摩通作为万帮数字能源的战略合作伙伴,给万帮提供了整厂的智能生产规划,助力万帮在新能源领域越走越深,走向全球。 ▲图片来自于中科摩通现场拍摄和实际方案 ▲图片来自于中科摩通现场拍摄和实际方案 1)整厂规划,家储和商储全套自动化解决方案,从智能仓储,AGV上料,模组装配焊接、PACK装配、AGV下料、成品测试、出库等全供应链整厂规划;2)280AH方壳储能模组PACK线,设计节拍可达12PPM+,整线自动化率高达95%以上,包含自动上线、自动贴胶、自动成组、自动CCS安装、自动激光焊接、自动入箱、整包自动下线等核心工艺;在新能源领域,技术革新时刻都在发生,技术的变革对于生产研发都是不断的挑战。中科摩通始终在挑战自我的道路上,不断自我革新,技术革新,产品革新,保持走在产业技术的前沿,给每一位客户提供助力未来发展的战略性智能装备。中科摩通成立于2019年,是一家专注于研发新能源产业智能装备整体解决方案的国家级专精特新小巨人企业,公司依托中科院江苏智能院、中科院天目湖储能院强大的科研技术力量,旨在为新能源产业提供自动化、信息化、智能化的生产解决方案。公司主营产品包含锂电储能电池模组自动产线,锂电池储能PACK产线,锂电池储能系统组装线动力模组PACK产线。公司已成功进入宁德时代、蜂巢能源、科士达、星星充电、安徽通盛、四川航电、新泉股份、康晟佳智慧能源、万帮数字能源等新能源汽车领域及储能系统集成头部客户。